Numerical study of a thermoelectric effect in the solidification of metallic alloys

Post-doc project

The use of external electromagnetic fields has become a rather standard industrial technique in material processing to control the mixing and the solidification of metallic alloys. Quite recently though, in-situ X-ray observations in solidification experiments revealed an interesting phenomenon predicted theoretically, which stimulated afresh interest of scientists.

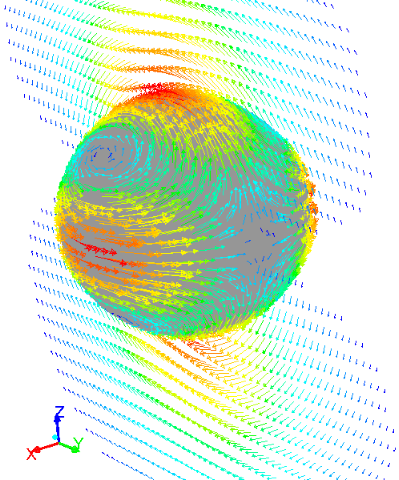

This phenomenon, referred to as TEMF (for thermo-electric magnetic force), arises from the interaction between a thermo-electric current occurring inside the material at the solid/liquid interface [1] and the applied static magnetic field. This force acts upon both the solid and the liquid phase of the material and could therefore serve as a way of controlling the orientation of the solidification, the segregation of the components, or even the distribution of particles during their incorporation into alloys for reinforcement purposes.

Though very promising, the use of TEMF as a way of controlling the processing of metallic alloys needs scientific developments because the phenomenon takes place at different scales in a solid-liquid media and therefore appears very complex. In particular, on one hand the thermoelectric current develops in a very thin liquid layer near the liquid-solid interface, on the other hand the action of TEMF spreads over a large distance via convective flows and its effect on the solid phase results in the transport of particles with eventual rotations or deformations occurring in the solid phase.

The aim of the present project is to develop an algorithm able to couple multi-physical phenomena originated at various space scales, to work out and predict the variations of the solidified structure at the macroscale.

More precisely, the coupled effect of the TEMF, magneto‐hydrodynamics and phase transition during the solidification of Al‐Cu alloy is studied in this work. As an outcome of the project, a better comprehension of the experimental observations made with in‐situ X‐ray technique will be attained. A breakthrough in numerical multiscale studies of the solidification phenomenon will also be made. It is expected that the constitutive relations deduced from the microscale modelling will serve as entry data for average meso‐ and macro‐scale models.

[1] During solidification, a strong temperature gradient is usually applied to a material to extract the latent heat. Because the thermo-physical properties of the liquid and the solid states of the material can be very different, a sharp thermal gradient at the solid-liquid interface may establish which, in certain materials, is directly converted into electric currents (i.e. the thermoelectric effect)

CONTACTS

- PI: Olga Budenkova

- Co-PI: Yves Duterrail, Annie Gagnoud

- Post-doc: Roza Tarpagkou

PARTNERS

SIMAP EPM

FUNDING

Tec21

Project update

Publications

Budenkova O., Bernabeu N., Du Terrail Couvat Y., Tarpagkou R., Gagnoud A., Fautrelle Y. (2016). Effect of the shape and orientation of an electrically conducting axisymmetric ellipsoid particle placed in the liquid metal on thermoelectric phenomena: analytical solution and numerical modeling. Appl. Math. Modeling, 47,590-605.

Oral papers

Tarpagkou R., Du Terrail Couvat Y., Gagnoud A., Budenkova O., Fautrelle Y. (2016). Finite element multigrid approach to numerical simulations of the coupled phenomena related to magneto-thermoelectric effects in solidification of metals. 10th PAMIR International Conference Fundamental and Applied MHD, Cagliari-Italy, 20-24 June 2016.

<< back