A combined experimental and numerical approach to the spalling of high performance concrete due to fire

PhD project

High-Performance Concrete (HPC) is a modern building material with superior properties compared to traditional concrete, and is widely used in high-rise buildings, thin walled elements for building façades, prefabricated columns, or elements for tunnels. However, a major limitation to the widespread use of HPC is that it is prone to explosive spalling when exposed to fire.

Research on spalling has been concentrated on extensive testing aiming to identify the main influencing parameters, and even if several theories have emerged, the explanations remain mostly qualitative and no general consensus on a single spalling theory has been reached so far.

The goal of the project is to better understand the fundamental mechanisms at play in spalling in order to build up a model that will be verified both theoretically and experimentally in a quantitative way.

The project focuses on the two main factors suspected to cause the spalling of concrete, i.e. pore pressure and thermal stress, and couples both experimental and numerical approaches.

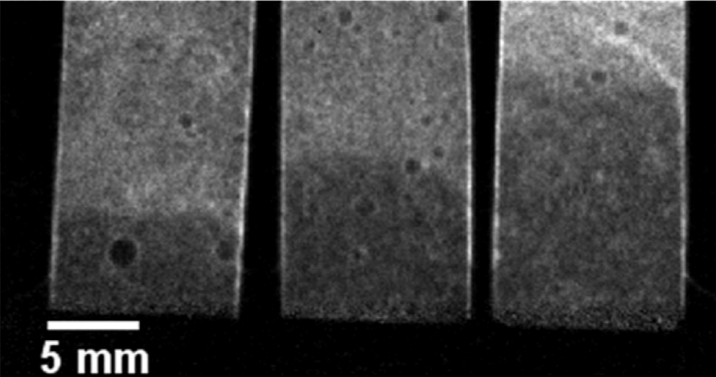

A thermo-hygral mechanical numerical model taking into account the granular structure of concrete is developed at the material scale and used to simulate the phenomenon. In parallel, experimental neutron radiography observations under controlled fire conditions feed the model with additional data regarding water content, pore pressure and temperature.

Thanks to this strategy, some of the assumptions used in different spalling theories can be quantitatively verified. For instance the problem of moisture clogs, considered to be one of the main mechanisms driving spalling through the dramatic rise of pore pressure, is addressed quantitatively. In the same way, the setting-up of intense tensile stresses along the drying front due to sudden changes in the temperature gradient is evidenced, and suggests the existence of a mechanism involving dynamic crack propagation that could explain, together with the increase of pore pressure, the explosive nature of spalling.

In this project, all the tests are carried out on different concrete mixtures, thus allowing the creation of a consistent database.

CONTACTS

- PI: Stefano Dal Pont

- Co-PI: Benedikt Weber

- PhD: Dorjan Dauti

PARTNERS

- 3SR

- Structural engineering laboratory, EMPA Dübendorf (Switzerland)

FUNDING

Tec21