Numerical modelling of the mechanical behaviour of cellulose fibres in a fluid flow

PhD project

Biomass processing involves a number of complex operations ranging from the fragmentation of the vegetal 3D structures to the assembly of the isolated constituents into new matrixes and materials.

Among the constituents of interest, fibres have a huge potential for new applications in packaging, composites and texturing agents. Their manipulation still meets obstacles, in particular at the process scale where their behaviour as aqueous suspensions is insufficiently understood. Due to their particular thin and long shape, these objects are subjected to twisting, rotations and folding when transported in a liquid flow, and their resulting repartition, orientation and density in the suspension can show important variability. When considering their use as reinforcing material in composites for instance, the control of these parameters is of prime importance regarding the resulting mechanical properties of the final material.

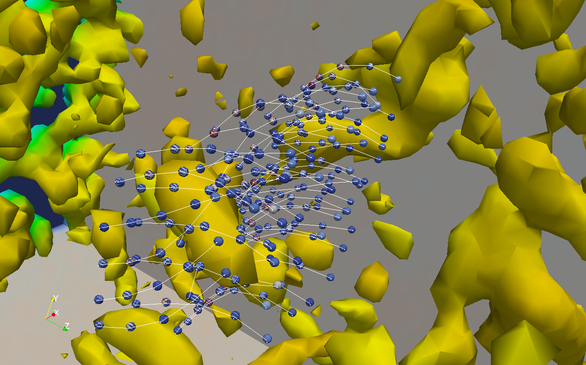

This project consists in developing a numerical simulation tool to describe the movement of soft fibres (millimetric to nanometric size, with aspect ratio ranging from 10 to 100) in complex, highly confined and turbulent flows such as those potentially encountered in industrial processing. The approach is based on the coupling of discrete element and finite volume methods.

The final goal of the project is to get an explicit description of the elementary processes such as deformation and agglomeration, acting upon the fibres during their processing as a suspension.

This project is part of Tec21 biorefinery roadmap aiming to better control the manufacturing processes of cellulose fibres, especially grinding, separation in microchannels, mixing with other constituents or matrixes, coating…

CONTACTS

- PI: Pierre Dumont

- Co-PI: Barthélémy Harthong, Guillaume Balarac

- PhD: Deepak Kunhappan

PARTNERS

- LGP2

- 3SR

- LEGI

FUNDING

- Tec21

- CNRS